Identifying Electrical Component Failures in Equipment

Have you ever faced a surprise when your equipment suddenly stops working? it’s frustrating, right? Understanding how to identify electrical component failures can save you time and money. Lets dive into the world of electrical components and learn how to spot issues before they become major headaches.

Why Do Electrical Components Fail?

Before we talk about identifying failures, it’s essential to know why they happen. Equipment has many electrical parts that work together. Over time, wear and tear can lead to failures. Common reasons include:

- Heat: Excessive heat can damage components.

- Moisture: Water can cause short circuits.

- Age: Old components naturally wear out.

- Power Surges: Sudden spikes can ruin delicate parts.

Understanding these causes can help you prevent issues before they arise. Regular maintenance is key!

What Are the Signs of Electrical Component Failures?

Knowing the symptoms of electrical failures can help you react quickly. Here are some signs to watch for:

- Unusual Noises: Clicking, buzzing, or humming sounds are red flags.

- Smell of Burning: A burnt smell often indicates overheating components.

- Equipment Not Functioning: If your device isn’t turning on, it might be a sign of failure.

- Frequent Breakdowns: If you notice repeated issues, something is likely wrong.

Addressing these symptoms early can prevent more significant problems down the line.

How Can You Diagnose Electrical Component Failures?

Diagnosing failures doesnt have to be complicated. Here are some straightforward methods:

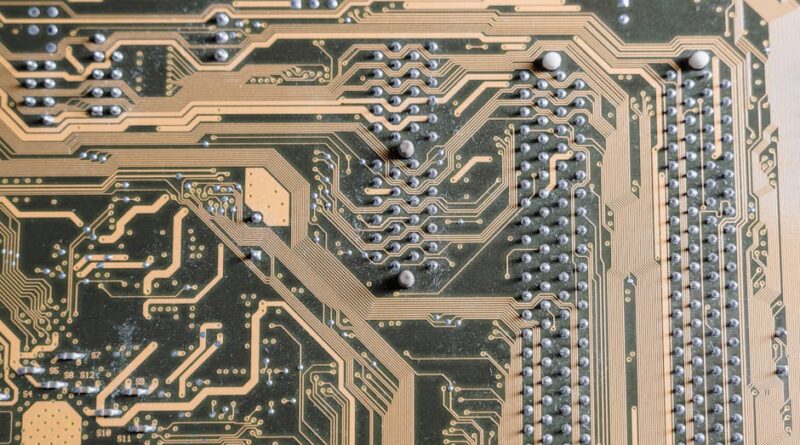

1. Visual Inspection

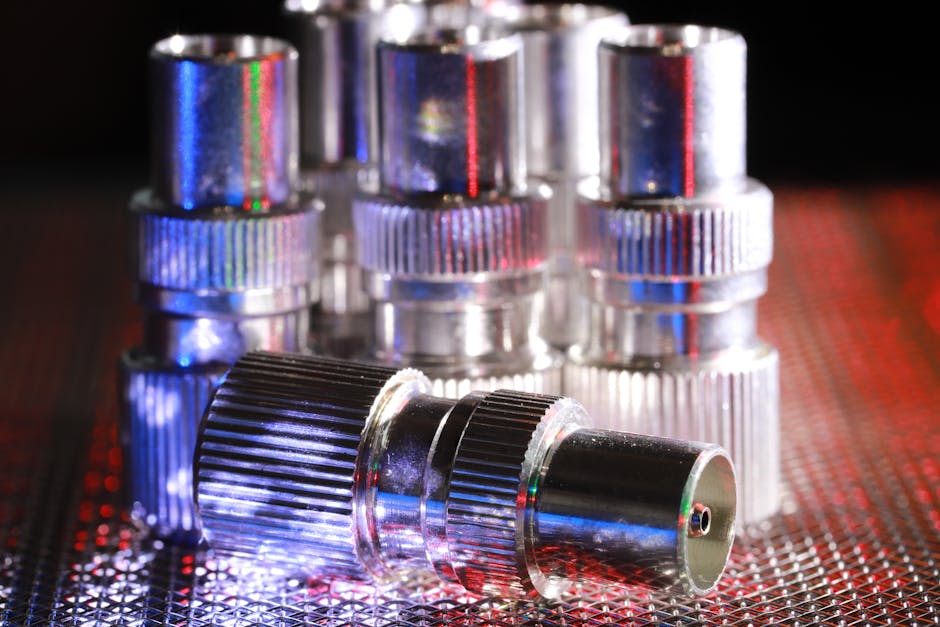

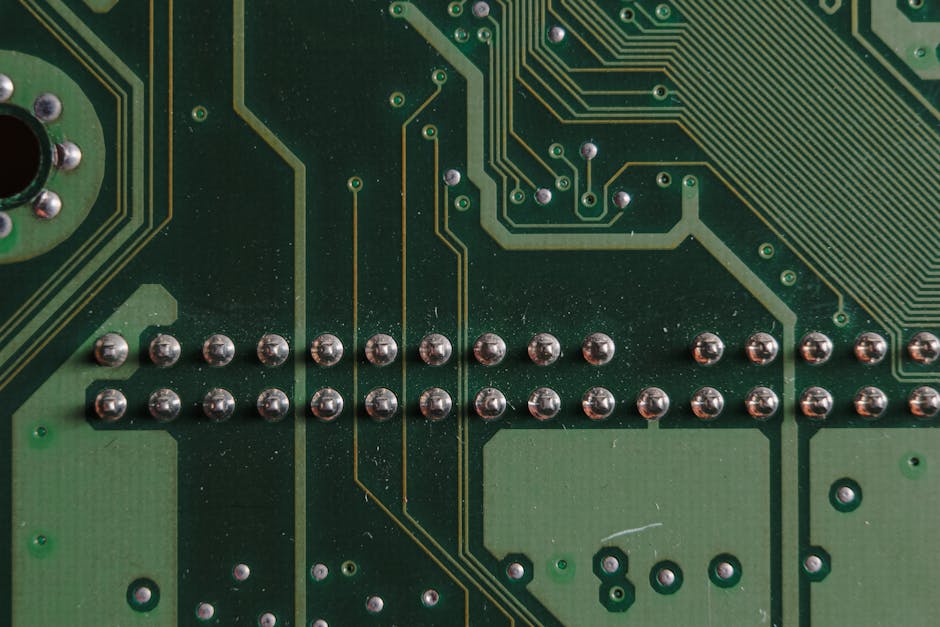

Start with a simple visual check. Look for:

- Discoloration or burns on components.

- Loose connections or frayed wires.

- Corrosion or rust on metal parts.

A visual inspection can often reveal obvious issues that need attention.

2. Use a Multimeter

A multimeter is a handy tool for checking electrical components. It measures voltage, current, and resistance. Heres how to use it:

- Check Voltage: Ensure power is reaching the component.

- Measure Resistance: Test the component to see if it meets specifications.

- Test Continuity: Ensure the electricity flows through the circuit.

Using a multimeter can pinpoint failures with accuracy.

3. Perform Functional Testing

Sometimes the best way to test a component is to see if it works. For example:

- If a motor isn’t running, swap it with a working one to see if the problem persists.

- Test switches and relays by manually activating them.

Functional testing can help confirm your diagnosis.

Can You Prevent Electrical Component Failures?

Absolutely! Preventive maintenance is crucial. Heres how you can keep your equipment running smoothly:

- Regular Inspections: Schedule routine checks to catch issues early.

- Keep Areas Clean: Dust and debris can lead to overheating.

- Monitor Operating Conditions: Ensure your equipment operates within recommended temperature and humidity levels.

- Upgrade Components: Replace old parts before they fail.

Following these tips can extend the life of your equipment and reduce the chances of sudden failures.

What to Do When You Identify a Failure?

If you spot a failure, don’t panic. Heres a simple action plan:

- Turn Off Power: Always prioritize safety first.

- Document the Issue: Write down what you found for future reference.

- Consult the Manual: Check for troubleshooting tips specific to your equipment.

- Seek Professional Help: If you’re unsure, it’s best to call an expert.

Taking these steps can help you address issues efficiently and safely.

Common Misconceptions About Electrical Failures

There are several myths about electrical failures. Lets clear a few up:

- Only old equipment fails. New equipment can fail too, especially if poorly designed.

- All failures are visible. Some issues are internal and may not show immediate signs.

- I can fix everything myself. Some problems require professional expertise for safety.

Understanding these misconceptions can help you react more appropriately when issues arise.

Conclusion: Take Charge of Your Equipments Health

Identifying electrical component failures doesnt have to be daunting. With some basic knowledge and tools, you can spot problems before they escalate. Remember to perform regular maintenance and stay observant of your equipment’s behavior.

Next time your equipment acts up, youll be ready! For more detailed information on electrical diagnostics, check out this resource. Also, consider reading our post on equipment maintenance tips for even more useful insights.

Stay proactive, stay safe, and keep your equipment running smoothly!