Effective Maintenance Tools for Industries

Did you know that a well-maintained machine can save up to 30% on energy costs? In industries, this is a game changer. Effective maintenance tools not only extend the lifespan of equipment but also boost productivity and enhance safety. Lets dive into the essential tools that can help industries stay ahead.

What Are Maintenance Tools?

Maintenance tools are devices used to keep equipment running smoothly. They can be simple hand tools or advanced software solutions. Think of a toolbox filled with wrenches, as well as high-tech systems that monitor equipment health.

These tools aid in frequent inspections, repairs, and preventive measures. They help catch issues before they turn into costly breakdowns. This proactive approach is crucial for any business that relies heavily on machinery.

Why Is Maintenance Important?

Regular maintenance is vital for a few reasons:

- Cost Savings: Regular upkeep can prevent sudden repairs, saving money in the long run.

- Safety: Well-maintained equipment is safer for workers. This reduces accidents on the job.

- Efficiency: Machines that run smoothly are more efficient, leading to better productivity.

In fact, the U.S. Department of Labor states that proper maintenance can reduce workplace accidents by up to 30%. This statistic shows just how important it is to invest in reliable maintenance tools.

What Are the Key Maintenance Tools for Industries?

There are many tools available, but some stand out as essential. These include:

- Hand Tools: Wrenches, screwdrivers, and pliers are basics that every maintenance team should have.

- Power Tools: Drills and saws can make repairs quicker and more efficient.

- Diagnostic Tools: These tools help identify problems before they escalate. Examples include vibration analyzers and oscilloscopes.

- Monitoring Software: This technology tracks equipment performance and alerts teams to potential issues.

Lets explore these tools in more detail.

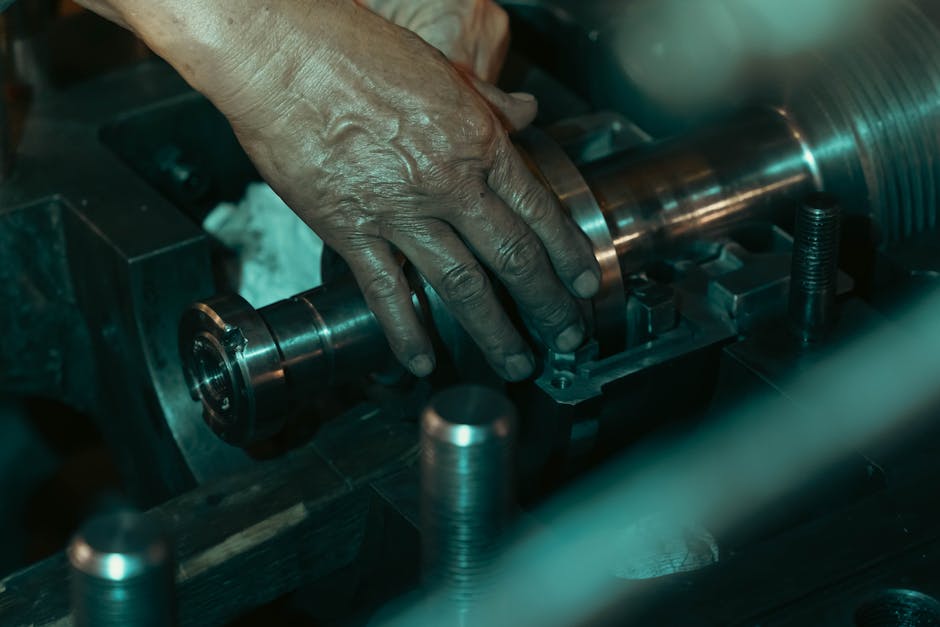

How Do Hand Tools Make a Difference?

Hand tools are the backbone of maintenance work. They are often used for quick fixes and adjustments. Heres how they help:

- Simplicity: Hand tools are easy to use and require no special training.

- Versatility: They can tackle a wide range of tasks, from tightening bolts to assembling parts.

- Portability: Most hand tools are lightweight and can be carried around the facility.

For instance, imagine a mechanic using a wrench to tighten a loose connection. This quick action can prevent a major equipment failure later on.

When Are Power Tools Essential?

Power tools come into play when tasks get tougher. They save time and reduce manual labor. Heres why industries need them:

- Speed: Power tools can complete tasks much faster than hand tools.

- Precision: They often provide more accurate results, which is crucial for complex repairs.

- Less Effort: They require less physical strength, reducing the risk of worker fatigue.

For example, using a power drill to install a new part is not only quicker but also ensures that the job is done right. This efficiency can lead to fewer delays in production.

What Role Do Diagnostic Tools Play?

Diagnostic tools are like the doctors of industrial equipment. They help identify issues before they become serious problems. Here are a few key benefits:

- Early Detection: These tools can spot signs of wear and tear early.

- Data-Driven Decisions: They provide data that helps in making informed maintenance decisions.

- Reduced Downtime: Catching issues early means less time spent on repairs.

Consider a vibration analyzer. It can detect unusual vibrations in a motor, indicating a problem. By addressing that issue early, companies can avoid expensive downtime.

Why Is Monitoring Software Important?

Monitoring software is becoming essential for modern industries. Heres how it benefits maintenance:

- Real-Time Monitoring: It tracks equipment performance continuously.

- Alerts and Notifications: It sends alerts when something goes wrong.

- Data Analytics: Software can analyze trends over time to predict failures.

For example, a factory might use software to monitor the temperature of machines. If a machine overheats, the software alerts the maintenance team immediately. This can prevent a breakdown.

What Are Some Common Misconceptions About Maintenance Tools?

Many people have misconceptions about maintenance tools. Lets clear a few up:

- Maintenance is only about fixing broken things. – In reality, it’s about preventing problems.

- All tools are expensive. – There are many affordable options that work just as well.

- You only need tools for mechanical equipment. – Software tools are just as crucial for maintaining operational efficiency.

Understanding these misconceptions helps businesses recognize the importance of investing in the right tools.

How Can Industries Choose the Right Tools?

Choosing the right maintenance tools can feel overwhelming. Here are some tips:

- Assess Your Needs: Identify what types of equipment you have and what tools are necessary.

- Research Brands: Look for reliable brands known for quality tools.

- Consider Training: Ensure your team can effectively use the tools you select.

- Think About Future Needs: Choose tools that can adapt as your business grows.

For instance, if your factory plans to expand it’s machinery, invest in scalable software solutions now.

What Are the Best Practices for Tool Maintenance?

Maintaining your tools is just as important as using them. Here are a few best practices:

- Regular Inspections: Check tools for wear and damage regularly.

- Proper Storage: Store tools in a dry and clean place to prevent rust and damage.

- Cleaning: Clean tools after each use to extend their lifespan.

By following these practices, industries can ensure their tools last longer and perform better.

What Are Some Actionable Takeaways?

To wrap things up, here are some key takeaways:

- Invest in a mix of hand and power tools for versatility.

- Use diagnostic and monitoring tools to catch problems early.

- Educate your team on proper maintenance and tool usage.

- Stay informed about new technologies that can enhance maintenance efforts.

By implementing effective maintenance tools, industries can save money, improve safety, and enhance productivity. Start evaluating your maintenance strategy today!

For more information on industrial maintenance, check out the Industry Week website.