Common Electrical Components in Industrial Equipment

Have you ever wondered what makes industrial machines tick? Factories and plants run on complex systems, but at their core, you’ll find some common electrical components. Understanding these parts can help you appreciate the engineering that keeps our world moving. Lets dive in!

What Are the Key Electrical Components?

Electrical components are the building blocks of industrial equipment. They convert power into useful work. Here are some of the most common components you’ll encounter:

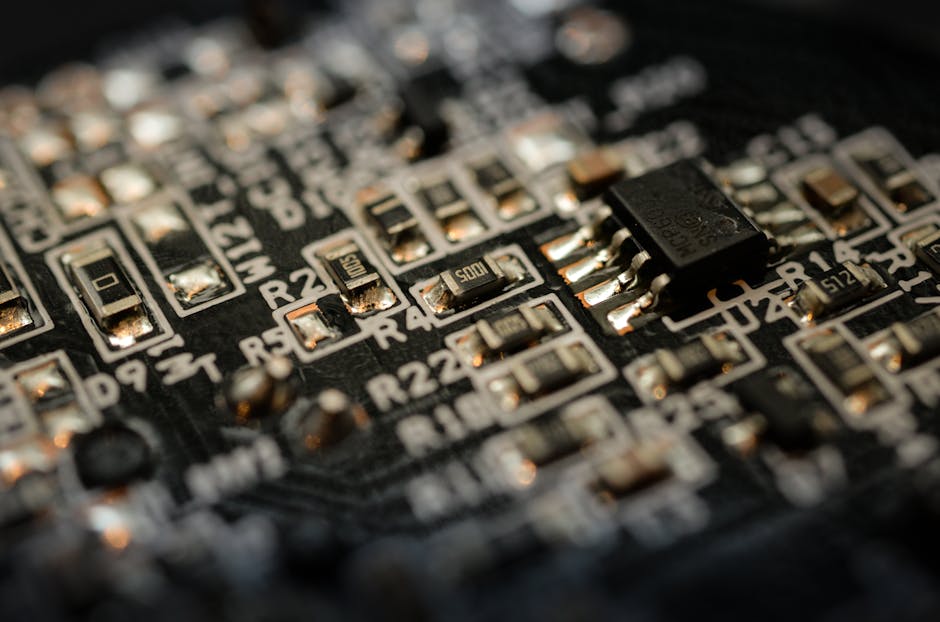

- Resistors: These limit the flow of electricity. Think of them as a traffic light in an electrical circuit.

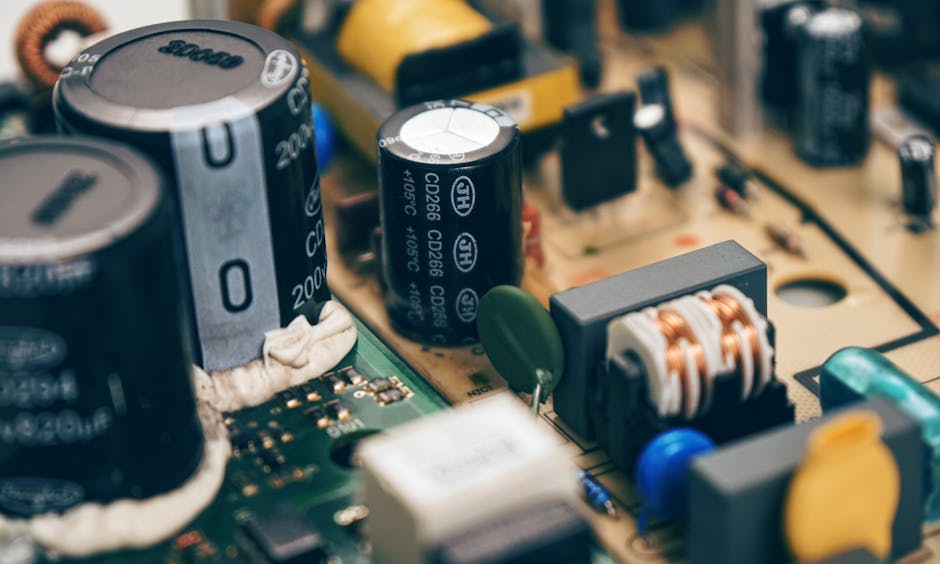

- Capacitors: They store and release energy. Imagine a water tank that fills up and then lets out water when needed.

- Inductors: These create magnetic fields when electricity flows through them. They’re like the coils in an electric stove.

- Transformers: They change the voltage of electricity, similar to how a step-up or step-down mechanism works on stairs.

- Switches: These control the flow of electricity, acting like the on/off switch on your lamp.

- Connectors: They link electrical components together, much like how a puzzle piece connects with another.

How Do Resistors Work?

Resistors play a crucial role in controlling electrical current. They provide resistance, which slows down the flow of electricity. This is essential for protecting sensitive components from damage. You can find resistors in almost every electronic device, like the radio in your car.

For example, if you have a toy that requires a specific voltage, using the right resistor ensures it operates safely. Without it, the toy might get too much power and break down.

What Are Capacitors and Why Are They Important?

Capacitors store electrical energy and release it when needed. They are found in power supplies, where they smooth out voltage spikes. Think of capacitors like a sponge soaking up water and then releasing it when necessary.

In your everyday life, a common example is in cameras. Capacitors help charge the flash, providing a quick burst of energy for that perfect photo.

How Do Inductors Function?

Inductors are vital for managing electrical currents. They resist changes in current flow, making them essential for applications like transformers and motors. When electricity runs through an inductor, it creates a magnetic field, which can be used in many ways.

Imagine the coils in a microwave. They operate using inductive heating, which warms your food efficiently. This principle is at work in industrial machines too, helping them run smoothly.

What Role Do Transformers Play?

Transformers are critical for adjusting voltage levels. They either increase (step-up) or decrease (step-down) voltage, ensuring equipment operates safely and effectively. This is especially important when transmitting electricity over long distances.

For instance, when electricity travels from a power plant to your home, transformers adjust the voltage, so it’s safe to use. Without them, devices could be damaged from too much power.

Why Are Switches Essential?

Switches control the ON and OFF states of electrical devices. They are simple but vital components. In industrial settings, switches can be large and complex, controlling massive machinery or delicate electronics.

Think about the light switch at home. When you flip it, electrical flow starts or stops. In factories, switches can control entire processes, ensuring everything runs smoothly and safely.

What Are Connectors and Their Importance?

Connectors link wires and components, making electrical circuits complete. They come in various shapes and sizes, depending on the application. In industrial equipment, connectors must be durable to withstand harsh environments.

For example, in a car, connectors link different electrical systems. If one connector fails, it can affect the entire vehicle. Similarly, in factories, a single faulty connector can halt production.

How Do All These Components Work Together?

Electrical components don’t work in isolation; they form a network. For instance, resistors and capacitors often work together in circuits to filter signals. Inductors and transformers collaborate to manage voltage and current. Understanding how these components relate helps clarify their roles in systems.

Imagine a symphony orchestra. Each instrument plays it’s part, but together they create beautiful music. Similarly, electrical components harmonize to power industrial machines efficiently.

What Are Common Applications of These Components?

Electrical components are used in countless applications, from manufacturing machinery to HVAC systems. Here are a few examples:

- Manufacturing Equipment: Machines use transformers, switches, and capacitors to operate effectively.

- HVAC Systems: These systems rely on resistors and capacitors to regulate temperature and airflow.

- Robotics: Industrial robots depend on all these components to perform tasks accurately.

What Should You Consider When Choosing Components?

When selecting electrical components, consider these factors:

- Voltage Rating: Ensure components can handle the voltage in your application.

- Current Rating: Choose components that can manage the expected current flow.

- Environment: Assess the conditions where components will operate, like temperature and moisture.

Choosing the right components can make a significant difference in machine efficiency and longevity. it’s like using quality ingredients in a recipe; the final dish will taste better!

Common Misconceptions About Electrical Components

Lets clear up some common myths:

- All resistors are the same: Resistors come in various types and values, each serving specific functions.

- Capacitors can hold unlimited charge: Each capacitor has a maximum charge it can hold, defined by it’s capacitance value.

- Transformers can change power type: Transformers only change voltage, not the type of power (AC to DC or vice versa).

Understanding these facts can help you make informed decisions when working with electrical components.

What Are the Future Trends in Electrical Components?

The world of electrical components is ever-evolving. Here are some trends shaping the future:

- Smart Components: More devices are integrating smart technology for better efficiency.

- Miniaturization: Smaller components are becoming more powerful, fitting into compact spaces.

- Eco-friendly Materials: Theres a push for sustainable components to reduce environmental impact.

These advancements will improve efficiency, save energy, and reduce costs in industrial applications.

Conclusion: The Importance of Understanding Electrical Components

Understanding common electrical components in industrial equipment is crucial for anyone involved in engineering or manufacturing. By knowing how these parts work together, you can improve efficiency, safety, and reliability in various applications.

As you explore this topic further, consider experimenting with small projects. Building simple circuits can enhance your understanding of these concepts. If you want to delve deeper, check out more resources on electrical engineering at Electrical Engineering Portal.

Remember, the next time you see a machine in action, you’ll have a better appreciation for the electrical components that make it all possible!